Xingaonai

Xingaonai

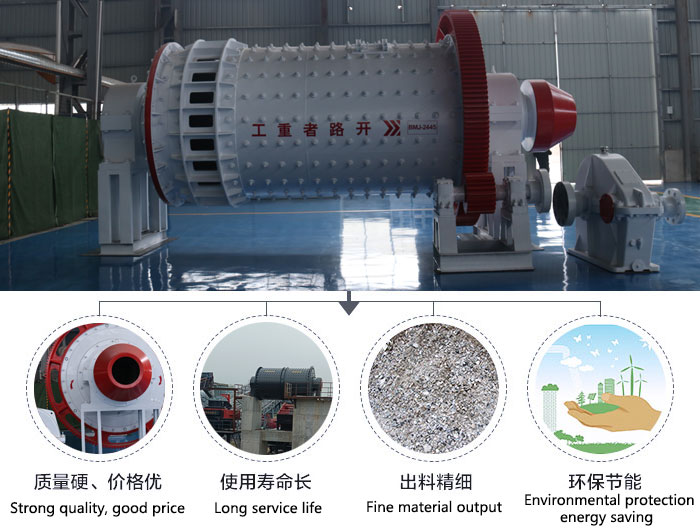

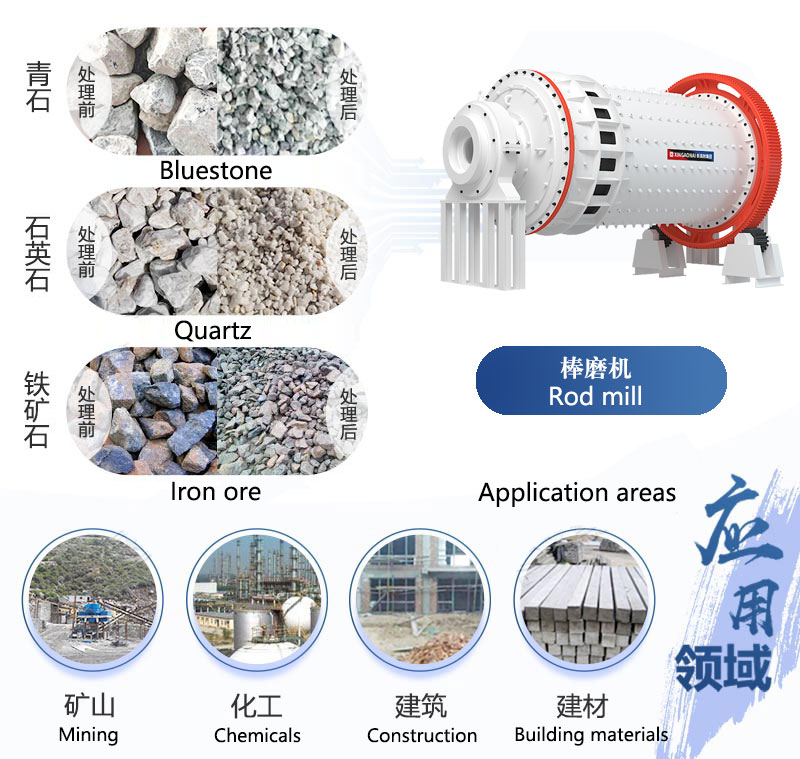

Rod mill sand making: The rod mill sand making machine is driven by a motor through a reducer and a peripheral large gear reduction transmission or by a low-speed synchronous motor directly through a peripheral large gear reduction transmission to drive the cylinder to rotate. Steel rods are installed in the cylinder as grinding media. Under the action of centrifugal force and friction, the grinding media is lifted to a certain height and falls in a state of throwing or leaking. The ground material continuously enters the cylinder from the feed port, is crushed by the moving grinding media, and is discharged from the machine through overflow and continuous feeding.

Vertical shaft impact sand making machine: It uses high-speed rotating materials to crush each other and the friction between materials to crush. According to its working mode, it can be divided into stone-on-iron and stone-on-stone. The vertical shaft impact crusher impeller rotates at a high speed driven by the motor to throw the material from the impeller flow channel. Stone-on-iron means that the material hits the impact plate; stone-on-stone means that the material hits the naturally formed material lining directly.

Raw material moisture: The rod mill has flexible grinding capacity and is suitable for both dry grinding and wet grinding. However, the vertical shaft impact sand making machine is specially designed for dry sand making and cannot handle wet materials.

Raw material particle size: Rod mill can effectively handle materials with a diameter of less than 30mm, showing its wide adaptability. The vertical shaft impact sand making machine can accept materials with a diameter of up to 60mm, further demonstrating its powerful crushing ability.

Raw material hardness: Vertical shaft impact sand making machine is good at handling high-hardness materials and can maintain stable performance in high-intensity working environments. In contrast, if faced with too hard materials, the steel rods inside the rod mill may suffer serious loss problems.

Rod mill machine-made sand: The finished sand is fine and smooth, the particles are uniform, the edges and corners are basically smoothed, showing an elliptical shape, and the particle size distribution has a certain regularity. Each fineness modulus corresponds to a particle size grading. This machine-made sand is suitable for the production of high-performance concrete because of its regular particle shape.

Vertical shaft impact sand making machine: The finished sand is mostly angular, and the particles are in a good cubic shape through the mutual collision and shaping between the materials. This kind of machine-made sand is widely used in the construction and concrete industries due to its unique particle shape and surface characteristics.

Output: The output of the rod mill is between 80-500t/h; the output of the vertical shaft impact sand making machine is between 70-640t/h, and the models are diverse, with more specifications to choose from.

Product fineness modulus control: When the rod mill makes sand, in general, the fineness modulus of the sand can be controlled within ±0.2 by adjusting the feed amount; the fineness modulus of the finished sand of the vertical shaft impact sand making machine is affected by many factors such as material particle size, moisture content, feed amount, and crusher rotor speed. Under the same material particle size, moisture content and crusher rotor speed, the feed amount increases, the stone powder content in the finished sand decreases, and the sand particle size modulus increases. When the feed amount reaches a certain value, it is basically stable. Equipment cost

Equipment price: The price of vertical shaft impact sand making machine is between 17,000 and 23,000 US dollars, and the price of rod mill is between 16,000 and 18,000 US dollars.

Operation cost: Rod mill consumes a lot of electricity, and the impact of grinding rods will make a loud noise during operation. Multiple machines working at the same time will cause noise pollution. The consumption of steel, water and electricity in the production process is large, and the production cost is relatively high. In addition, the stone powder loss in the sand washing process is serious, and the powder removal is difficult. The dehydration cycle of sand is long and the stone powder recovery is difficult during wet sand making. The material cushion layer in the rotor and crushing chamber of the vertical shaft impact sand making machine makes the wear parts less worn and the operating cost is low.

Rod mill sand making: This equipment is particularly suitable for small sand making plants with high requirements for the uniformity of finished particles. Because its operation is relatively simple and does not require complicated supporting facilities, the overall investment cost is more economical.

Vertical shaft impact sand making machine: This equipment is particularly suitable for large-scale sand making plants with huge output demands. It occupies an important position in the sand making production line. Its efficient sand making capacity can meet the needs of large-scale production.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/888.html

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Sitemap