Xingaonai

Xingaonai

Applicable stage: commonly used in the primary crushing stage of limestone processing. It can preliminarily crush larger limestone raw materials and provide materials of suitable particle size for subsequent processing links.

Equipment advantages: simple structure, convenient installation and maintenance, low operating cost; high crushing efficiency, strong crushing capacity, able to handle larger pieces of limestone; strong ability to pass non-crushed materials, and little affected by the moisture content of the material.

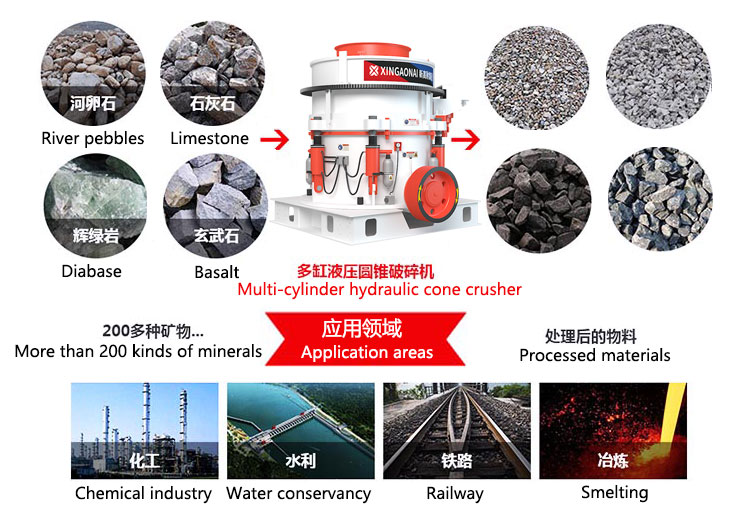

Cone crusher

Applicable stage: suitable for the medium and fine crushing stages of limestone. The limestone after primary crushing can be further crushed into smaller particle sizes to meet different production needs.

Equipment advantages: large crushing ratio, high efficiency, low energy consumption, and uniform product particle size; the laminated crushing principle is adopted to make the finished product particle shape better and cubic; high degree of automation, easy operation, and remote control and automatic adjustment of the discharge port size can be realized.

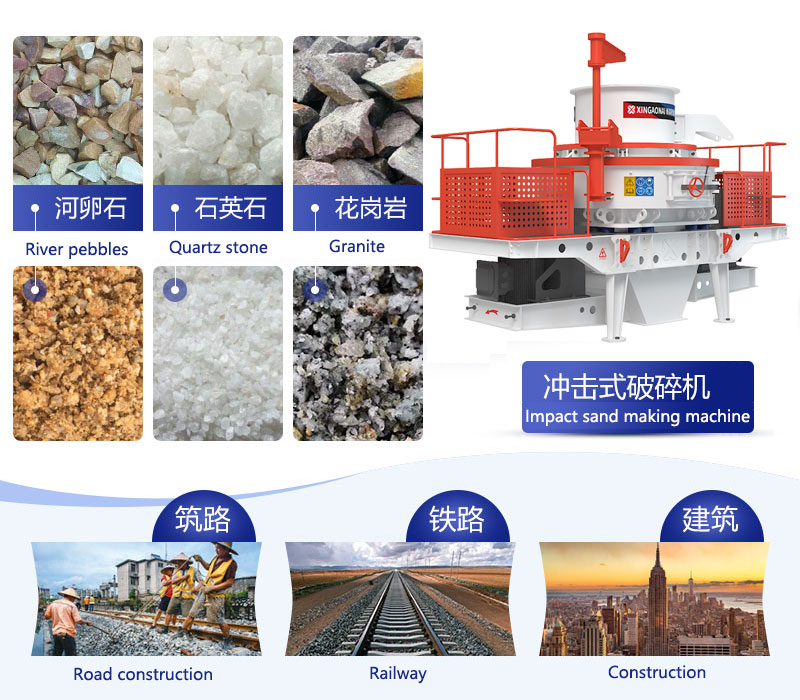

Impact sand making equipment

Applicable stage: used when limestone needs to be processed into fine sand. It can process limestone into fine sand aggregate that meets the standards for building sand.

Equipment advantages: The finished sand product has high purity and few impurities; the vertical structure is adopted, which is easier to install and fix on site; it can process limestone into fine sand and shape the fragmented sand to meet the standard of construction sand; the environmental protection and dust removal operation effect are double guaranteed, and you can work with confidence.

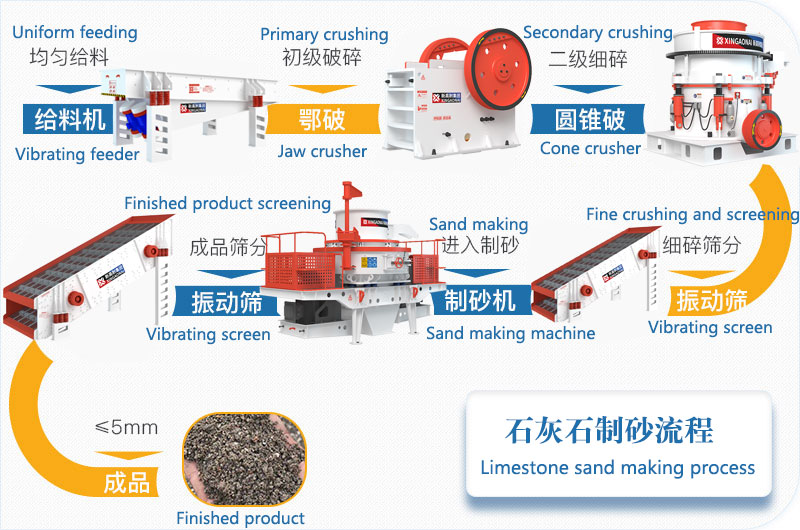

Coarse crushing stage

The limestone raw material is evenly fed by the feeder to the jaw crusher for coarse crushing. The jaw crusher is a common crushing machine. It uses the pressure between the upper and lower jaw plates to crush the stone, and can crush large pieces of limestone into smaller particles. After coarse crushing, the material is transported to the vibrating screen for pre-screening. The vibrating screen will separate the material into different particle size levels, and the coarse material on the first layer of the screen will be returned to the jaw crusher for re-crushing.

Medium crushing stage

The coarsely crushed material is transported to the impact crusher for fine crushing. The impact crusher is a new type of crushing equipment that can use high-speed rotating rotors and impact plates to achieve further crushing of stone. The material after fine crushing by the impact crusher is transported to the vibrating screen for secondary screening. The medium material after the secondary screening is returned to the impact crusher for re-crushing.

Sand making stage

The finely crushed material is transported to the vertical impact crusher for sand making, and the material after the vertical impact crusher is transported to the vibrating screen for three screenings. The material below 4.75mm after three screenings is transported to the sand washing equipment. After the material passes through the sand washing equipment, most of the sand is transported to the dewatering screen for dehydration, and finally the limestone machine-made sand product that meets the requirements is obtained. Generally, the finished product is 0-5mm machine-made sand and other different specifications, which can be adjusted and controlled according to actual needs.

The price of a set of limestone processing fine sand equipment is about 30,000 to 150,000 US dollars. According to the different types and models of limestone processing equipment on the market, or the choice of different manufacturers, there are also differences in raw materials, quality and business models, and the equipment quotations obtained by users are different.

How much does a specific set of limestone crushing and sand making equipment cost? Please feel free to click to consult or call +8617761642222 at any time to get the detailed information with one click. There will be a sales manager responsible for the equipment to provide you with factory price discounts. Pioneer adopts the direct sales model of the manufacturer and has a standardized and intelligent equipment production workshop. It uses high-quality raw materials and has exquisite workmanship, so you can rest assured about the equipment quality. In addition, there are technical engineers who go to the user's site to be responsible for equipment installation, debugging, operation guidance, etc., to shorten the user's construction period and quickly return the cost.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/887.html

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Sitemap