Xingaonai

Xingaonai

As a global leading comprehensive service provider of mining machinery and equipment, Xingaonai Heavy Industry (Zhengzhou) Group Co., Ltd. is specialized in the research and development and manufacturing of complete sets of crushing, screening, feeding and conveying equipment. The company mainly produces equipment required for production lines with an output of 100-6000 tons per hour, with complete models and superior quality. The company's main production equipment includes: jaw crusher, cone crusher, impact crusher, VSI sand making machine, mobile crushing station, etc., with complete models and superior quality. It is exported to many regions around the world and enjoys a good reputation at home and abroad.

In the field of ore and stone processing, crusher is an indispensable equipment. Among the many crushers, cone crusher and impact crusher are highly favored for their high efficiency and stable performance. So what is the difference between the two? Below Xingaonai Heavy Industry introduces the difference between the two.

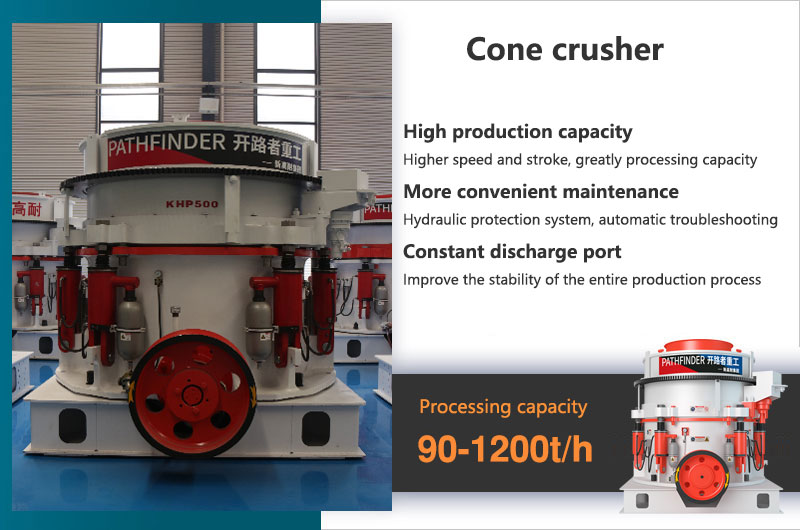

The cone crusher adopts laminated crushing, and the mortar wall continuously moves toward the crushing wall, squeezing the material sandwiched between the two to crush it.

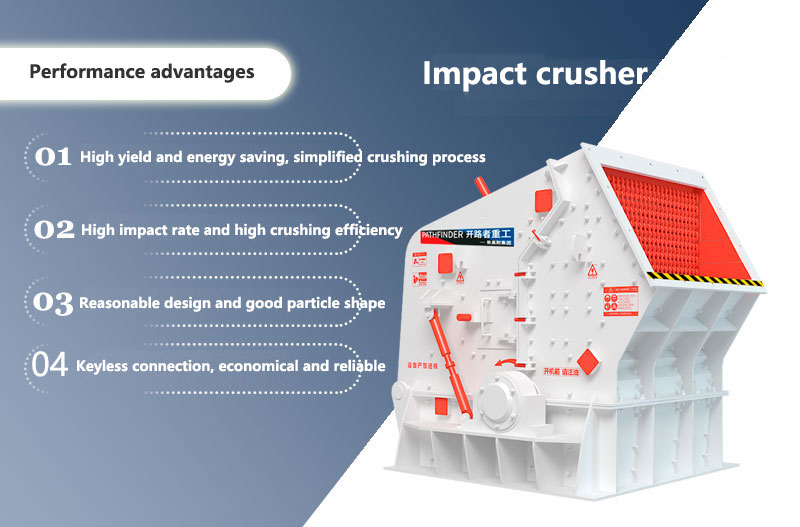

The impact crusher adopts the principle of impact crushing, and the material is repeatedly impacted and crushed between the plate hammer and the impact plate.

The cone crusher is mainly composed of a frame, a moving cone, a fixed cone, an eccentric sleeve, a bowl bearing, a transmission part and a hydraulic adjustment system, as well as a safety device that provides iron protection and cavity clearing functions.

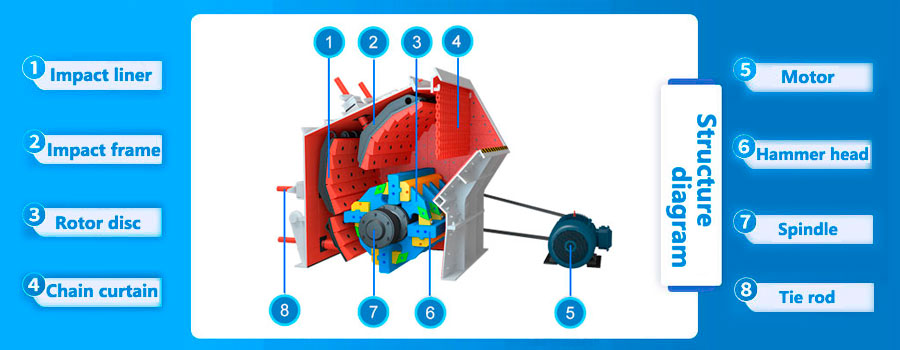

The impact crusher mainly includes a frame, an impact plate, a feed port, a discharge port, a rotor, a hammer head, an adjustment device and other parts. The frame is the supporting part of the crusher body, and the impact plate and the hammer head are the core components of the crusher.

The cone crusher mainly crushes some hard materials, such as granite, basalt, tuff, river pebbles and other medium and medium hardness ores and rocks.

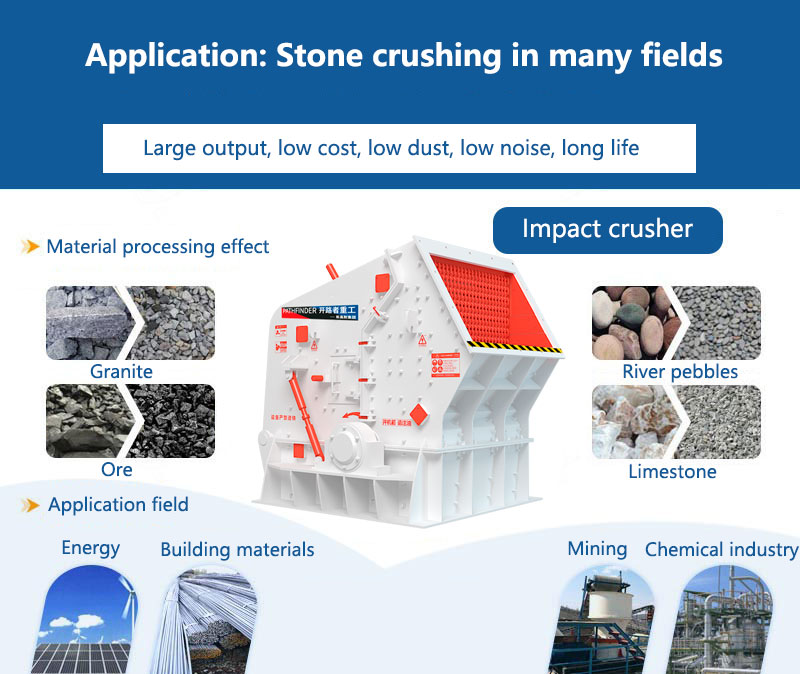

The impact crusher is used to crush materials with lower hardness and brittleness, such as limestone, limestone, clinker, slag, broken glass, calcium salt, clay ore, building materials, coke, coal, etc.

Generally speaking, the materials crushed by the cone crusher are finer than those crushed by the impact crusher. In the actual production process, cone crushers are widely used in mineral processing, while impact crushers are more commonly used in building materials and construction projects.

The impact crusher has good particle shape, fewer edges and corners, mostly cubic, less needle-like, and more powder. The finished product of the cone crusher has more needle-like materials and poor particle shape.

Compared with the impact crusher, the cone crusher has low energy consumption, large output, and stable production, and is often used in large-scale high-output production line operations. However, with the improvement of technology, the new CI5X impact crusher has also broken through the bottleneck of production capacity, and the hourly output can reach hundreds of tons or even thousands of tons.

The cone crusher uses the extrusion between two cones to achieve crushing, with a large crushing ratio, high efficiency, small wear and tear on hard material crushing, low consumption, low maintenance cost, low cost, good ore crushing effect, uniform product particle size, suitable for medium and fine crushing of various ores and rocks.

The impact crusher uses the impact energy of the plate hammer to crush. Adjusting the gap between the impact frame and the rotor can change the particle size and shape of the material, and can coarsely grind and shape the material. It has the advantages of simple structure, large crushing ratio, high output, light weight, low energy consumption, good appearance of the finished product (cubic), few edges and corners, and high strength grade of the finished product. It is an essential equipment for producing high-quality sand and gravel.

When the cone crusher squeezes and crushes the rock, it is easy to produce more needle-like materials with poor particle shape.

The impact crusher has large wear and tear when crushing high-hardness materials, high maintenance costs, and large noise and dust pollution.

The cone crusher is generally more expensive than the impact crusher of the same production capacity. This is mainly because the cone crusher has higher performance and higher output than the impact crusher, and it is not difficult to crush harder materials. The life of the wearing parts is relatively long. From a long-term perspective, the cone crusher is more cost-effective.

The initial investment of the impact crusher is low, but the later maintenance cost is high.

In general, cone crusher and impact crusher have their own advantages and disadvantages. The specific choice depends on actual needs, such as the nature of the crushed stone, output requirements, output specifications and investment budget.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/885.html

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Sitemap